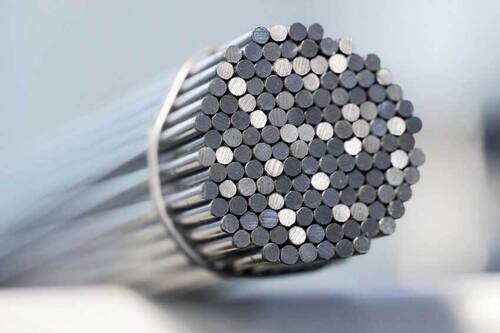

201 Stainless Steel Round Bar

201 Stainless Steel Round Bar Specification

- Tensile Strength

- 515 MPa min

- Diameter

- Available from 5mm to 100mm

- Material Composition %

- Cr 16-18%, Ni 3.5-5.5%, Mn 5.5-7.5%, C 0.15%

- Coating Type

- None (Natural Finish)

- Heat Resistance

- Yes

- Product Form

- Solid Bar

- Size

- Available in custom diameters and lengths

- Corrosion Resistant

- Yes, Moderate

- Recyclable

- Yes

- Hardness

- Hardness (HBW) 217

- Product Name

- 201 Stainless Steel Round Bar

- Steel Type

- Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- 201

- Thickness

- As per diameter specification

- Shape

- Round

- Steel Standard

- ASTM A276 / A479, JIS, DIN, EN

- Surface

- Bright, Polished, Peeled, Black

- Composition

- Chromium-Nickel-Manganese Stainless Steel

- Application

- Construction, Manufacturing, Engineering Components, Shafts, Pins, Fasteners

- Dimension (L*W*H)

- Custom sizes available (Diameter x Length as per requirement)

- Weight

- Varies as per size and length

- Color

- Silver/Grey Metallic

- Material Grade

- 201

- Finish Type

- Bright, Polished

- Usage

- Machining, Fabrication, Structural application

- Machinability

- Fair

- Melting Point

- 1400 C 1450 C

- Density

- 7.93 g/cm

- Magnetism

- Slightly magnetic after cold working

- Standards Compliance

- ISO, ASTM, JIS

- Yield Strength

- 275 MPa min

- Formability

- Good

- Weldability

- Good

- Elongation

- 35% min

- Bar Length

- Standard 1 meter, 3 meter, 6 meter or as per order

- MOQ

- As per manufacturer

About 201 Stainless Steel Round Bar

Stainless Steel ASTM A276 201 Round Bars are available in different types such as Stainless Steel 201 Round Bars, Stainless Steel 201 Round Bars Exporter in Mumbai, India, Stainless Steel UNS S20100 Round Bars, ASTM A276 Stainless Steel 201 Bright Bar & Rods, ASTM A276 Stainless Steel 201 Black Bar, ASTM A276 Stainless Steel 201 Forged Round Bar Exporters, Stainless Steel DIN 1.4372 Round Bars, ASTM A276 201 Stainless Steel Round Bars, Stainless Steel UNS S20100 Bars.

In the interim, Stainless Steel 201 Round Bars (SS 201 Rods) can be utilized for an assortment of utilizations. As for national and global nature of raw materials, we likewise offer these UNS S20100 Round Bars in tweaked sizes and thicknesses according to particular requests by our regarded customers at market driving costs.

Robust Mechanical Properties

With a minimum yield strength of 275 MPa and tensile strength of 515 MPa, the 201 Stainless Steel Round Bar provides durability for demanding engineering tasks. Its elongation of at least 35% and hardness below 217 HBW ensure it withstands deformation during fabrication and service, making it ideal for structural and load-bearing applications.

Versatile Applications and Sizing

This round bar is suitable for construction, manufacturing, pin and shaft production, and fastener fabrication. It is available in standard 1m, 3m, and 6m lengths or custom lengths as required, with diameters ranging from 5mm to 100mm. Manufacturers offer bespoke sizing to accommodate precise project needs.

Excellent Workability and Finish Options

The 201 Stainless Steel Round Bar features good weldability and formability, with fair machinability for diverse processing operations. Its slightly magnetic nature (after cold working) does not impair its use in structural or fabricated components. Various surface finishes, including bright, polished, peeled, and black, cater to aesthetic and functional preferences.

FAQ's of 201 Stainless Steel Round Bar:

Q: How is the 201 Stainless Steel Round Bar typically used in industry?

A: The 201 Stainless Steel Round Bar is commonly used in construction, manufacturing, engineering, and fabrication projects. Primary uses include making shafts, pins, fasteners, and structural components that require moderate corrosion resistance and good mechanical strength.Q: What are the benefits of choosing 201 Stainless Steel Round Bar over other grades?

A: The main advantages include moderate corrosion resistance, good yield and tensile strengths, excellent elongation, and cost-effectiveness compared to higher alloyed stainless steels. It is suitable for applications where high strength and moderate corrosion resistance are more critical than extreme corrosion environments.Q: What is the process for ordering custom sizes of the round bar?

A: Buyers can request custom diameters and lengths according to project specifications. Standard lengths are 1m, 3m, and 6m, but manufacturers or suppliers typically accommodate custom size orders, adhering to a minimum order quantity (MOQ) as specified.Q: When is 201 Stainless Steel Round Bar preferred for engineering components?

A: This round bar is preferred when projects require good workability, moderate corrosion resistance, and reliable mechanical properties. Its fair machinability and good weldability make it suitable for components like shafts, fasteners, and pins in various sectors.Q: Where is 201 Stainless Steel Round Bar manufactured and exported from?

A: The round bars are produced by manufacturers, suppliers, and exporters in India, complying with ISO, ASTM, JIS, and other international standards. They are distributed locally and exported globally for use in a wide range of industries.Q: What is the typical magnetism of the 201 Stainless Steel Round Bar, and will it affect usage?

A: The 201 grade is slightly magnetic, especially after cold working. This mild magnetism is not usually an issue in most engineering or construction applications but should be considered if complete non-magnetic properties are necessary.Q: How do the mechanical properties contribute to the round bar's performance in application?

A: The yield strength ( 275 MPa), tensile strength ( 515 MPa), and elongation ( 35%) ensure high load-bearing capacity, resilience against deformation, and improved safety in use, making it reliable for dynamic and static engineering demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Round Bar Category

Stainless Steel Square Bars

Price 245 INR / Kilograms

Minimum Order Quantity : 50 Kg Kilograms

Application : Other, Industrial and construction use

Steel Type : Stainless Steel

Steel Product Type : Other, Square Bars

Weight : Varies with dimensions and grade

304 Stainless Steel Bright Bar

Price 240 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Application : Hardware Parts

Steel Type : Stainless Steel

Steel Product Type : Steel Bars

Weight : As per rod Kilograms (kg)

316 Stainless Steel Round Bar

Price 245 INR / Kilograms

Minimum Order Quantity : 50 Kg Kilograms

Application : Decoration

Steel Type : Stainless Steel

Steel Product Type : Steel Bars

Weight : As Per Rod Kilograms (kg)

310s Stainless Steel Round Bar

Price 240 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Application : Construction

Steel Type : Stainless Steel

Steel Product Type : Steel Bars

Weight : As Per Rod Kilograms (kg)