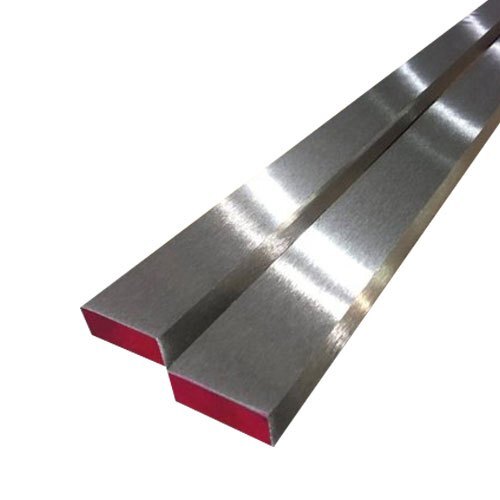

304l Stainless Steel Flat Bar

304l Stainless Steel Flat Bar Specification

- Product Form

- Solid Flat Bar

- Heat Resistance

- Yes

- Coating Type

- None (Self Passivating)

- Size

- Width: 25mm-200mm; Thickness: 3mm-25mm; Length: 1m-6m (customizable)

- Diameter

- Not applicable (Flat bar)

- Hardness

- Brinell 201 HBW

- Tensile Strength

- 485 MPa (min)

- Recyclable

- Yes, 100%

- Material Composition %

- Cr: 18-20%; Ni: 8-12%; C: 0.03%; Mn: 2%; Si: 1%

- Corrosion Resistant

- Yes, excellent resistance

- Product Name

- 304L Stainless Steel Flat Bar

- Steel Type

- Stainless Steel

- Steel Product Type

- Flat Bar

- Grade

- 304L

- Thickness

- 3mm 25mm (customizable)

- Shape

- Flat Bar

- Steel Standard

- ASTM A276 / A479, EN 10088-3

- Surface

- Pickled, Hot Rolled, Cold Drawn, Polished

- Composition

- 18-20% Cr, 8-12% Ni, 0.03% C, 2% Mn, 1% Si, 0.045% P, 0.03% S

- Application

- Construction, fabrication, manufacturing, architectural structures, frames, supports

- Dimension (L*W*H)

- Custom length x width x thickness (typically width: 25mm-200mm, thickness: 3mm-25mm)

- Weight

- Depends on size and length (e.g., approx. 2.35 kg/m for 25mm x 3mm)

- Color

- Metallic Silver

- Material Grade

- AISI 304L

- Finish Type

- Mill, Polished, Brushed

- Usage

- Machinery, frameworks, construction, general engineering

- Processing Services

- Cutting, Bending, Punching, Welding, Finishing

- Yield Strength

- 170 MPa (min)

- Lead Time

- Ready Stock / On Order (as per requirement)

- Packing

- Standard export packing, as per customer requirements

- Density

- 8.0 g/cm³

- Weldability

- Excellent, suitable for all standard welding techniques

- Machinability

- Good, better than conventional 304

- Edge Type

- Sheared or Rounded

- Elongation

- 40% (in 50mm)

- Magnetic Properties

- Non-magnetic in annealed condition

About 304l Stainless Steel Flat Bar

This 304l stainless steel flat bar is used extensively and professionally in a variety of industries, including those that produce steel structures, mechanical goods, cars, mining equipment, and hoisting equipment. Depending on whether it was hot rolled or cold drawn, this 304l stainless steel flat bar may be used for various things. Stainless steel is a long-lasting, low-maintenance substance. The great corrosion resistance of this product, which enables its usage in a range of environments, is one of its key benefits.

Superior Corrosion and Heat Resistance

304L stainless steel flat bars are formulated with 18-20% chromium and 8-12% nickel, delivering top-tier resistance against corrosion and oxidation. Withstanding intermittent temperatures up to 870C and continuous use up to 925C, these bars maintain structural integrity in demanding conditions, making them ideal for harsh industrial and marine environments.

Excellent Weldability and Machinability

Known for their excellent weldability, 304L flat bars are compatible with all standard welding methods, facilitating seamless integration in complex assemblies. Their low-carbon composition enhances machinability compared to standard 304, reducing fabrication time and tool wear. This balance ensures efficient processing methods like cutting, bending, punching, and finishing.

Customizable Dimensions and Finishes

Manufactured to ASTM A276/A479 and EN 10088-3 standards, these bars can be produced in a wide range of widths, thicknesses, and lengths (1m-6m) to meet specific project needs. Available in various surface finishes-pickled, hot rolled, cold drawn, and polished-the bars meet diverse aesthetic and functional requirements for construction, manufacturing, and architectural purposes.

FAQ's of 304l Stainless Steel Flat Bar:

Q: How can 304L stainless steel flat bars be processed for custom applications?

A: 304L stainless steel flat bars can be processed using a variety of techniques such as cutting, bending, punching, welding, and surface finishing. These processing services allow customization according to project dimensions or specific functional requirements and are available upon request from manufacturers or suppliers.Q: What benefits does 304L stainless steel flat bar offer over conventional 304?

A: Compared to conventional 304, 304L flat bars contain lower carbon content, which improves weldability and reduces the risk of carbide precipitation during welding. It also exhibits better machinability, lowering tool wear and increasing production efficiency in fabrication processes.Q: When should I use a 304L stainless steel flat bar in construction or engineering projects?

A: 304L stainless steel flat bars are recommended when high corrosion resistance, excellent weldability, and superior mechanical properties are required. They are ideal for frameworks, supports, architectural structures, and environments exposed to heat or corrosive agents.Q: Where are 304L stainless steel flat bars commonly utilized?

A: These bars are widely used in construction, fabrication, manufacturing, architectural structures, machinery frameworks, and general engineering. Their non-magnetic nature also makes them suitable for specific electrical and electronic applications.Q: What is the process to order custom-sized 304L stainless steel flat bars?

A: To order custom sizes, specify the desired width, thickness, and length (typically width: 25-200mm, thickness: 3-25mm, length: 1-6m) to your supplier or manufacturer. Processing, packing, and delivery options can be tailored as per your requirements and lead times depend on available stock or production schedules.Q: How does the non-magnetic property of 304L benefit certain applications?

A: In its annealed condition, 304L stainless steel is non-magnetic, which is advantageous in installations where magnetism could interfere with equipment operation, such as certain medical devices, measuring equipment, or sensitive electronic frameworks.Q: What finish options are available for 304L stainless steel flat bars?

A: 304L stainless steel flat bars can be supplied in a range of finishes, including mill, pickled, polished, hot rolled, cold drawn, and brushed. The selection depends on aesthetic preferences and application requirements.

Price 240 INR/ Kilograms

- Minimum Order Quantity

- 50 Kg Kilograms

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Flat Bar Category

Stainless Steel Flat Bar

Price 240 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Steel Product Type : Other

Application : Construction

Product Name : Stainless Steel Products

Steel Type : Stainless Steel

Stainless Steel Plain Flat Bar

Price 250 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Product Type : Steel Bars

Application : Other, Industrial

Product Name : Other, Stainless Steel Plain Flat Bar

Steel Type : Stainless Steel